FABRICATION

BACK TO SERVICES

Our Fabrication Workshop located in Geelong is equipped to produce high quality bespoke or project steel products.

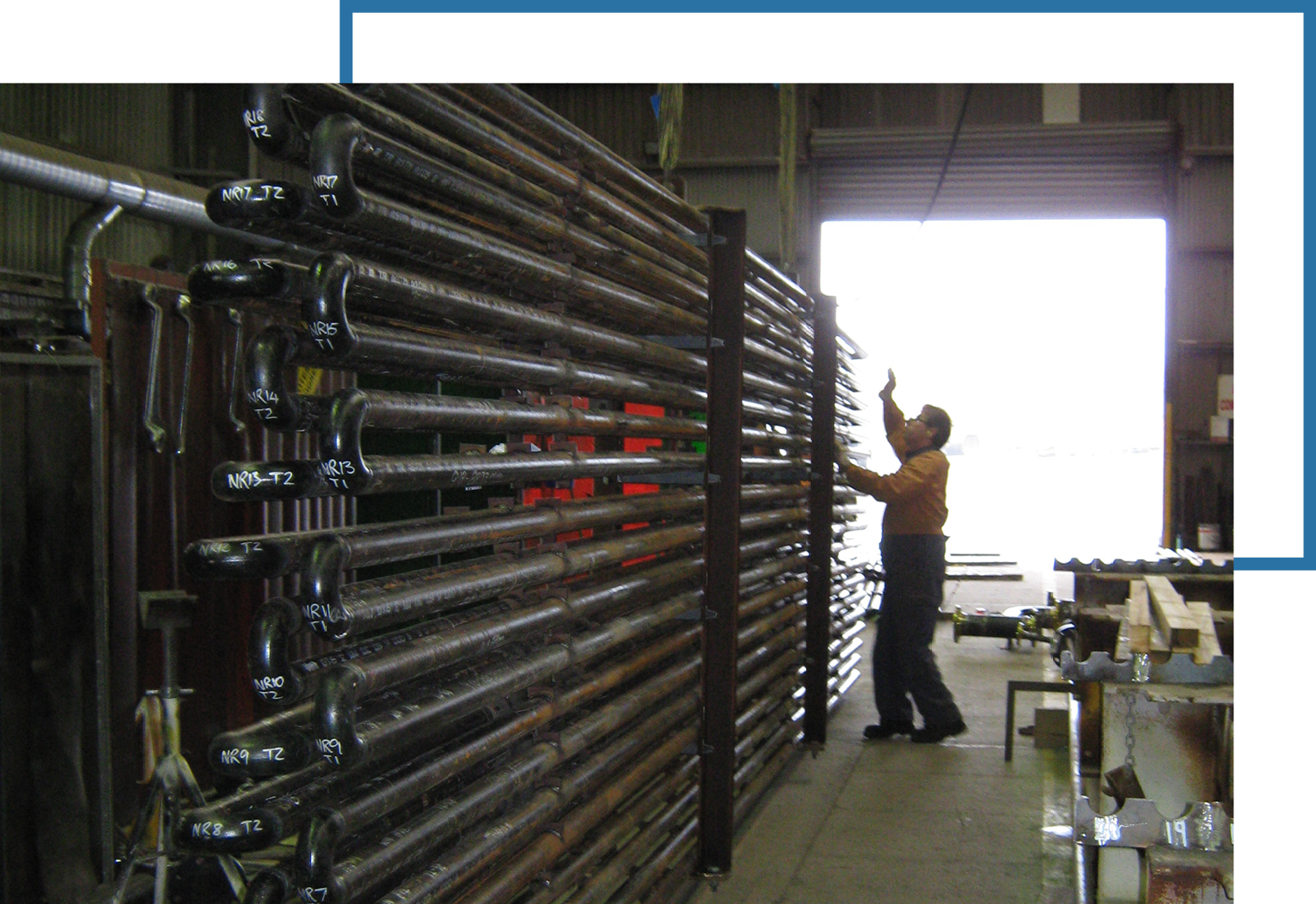

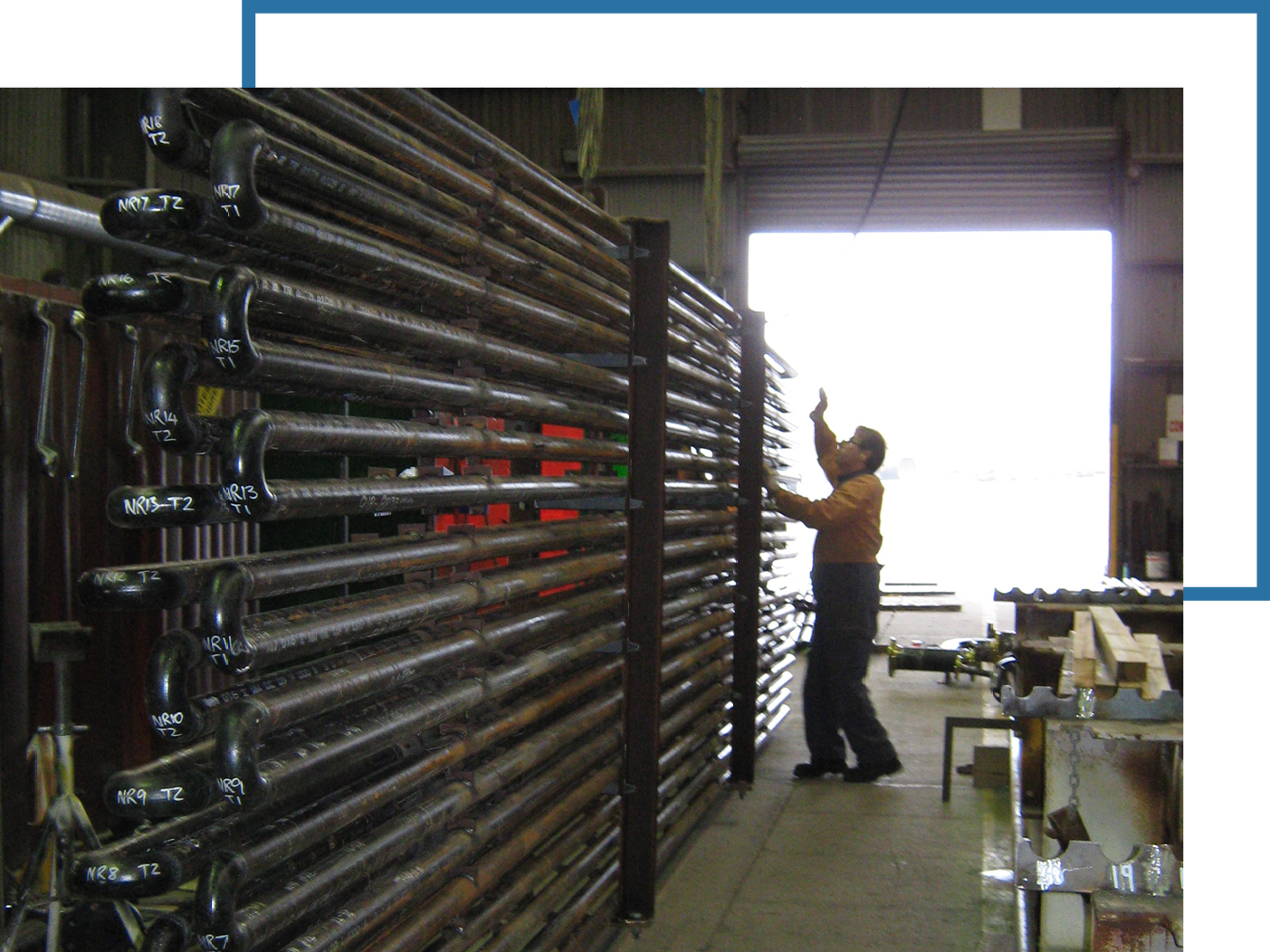

Our facility is capable of producing very high volumes of pipework to meet demanding schedules for shutdown projects and major refinery refits. Our ability to design, fabricate, construct and manage delivery logistics differentiates our workshop from all others in the region.

Our innovative methods for effecting repairs on corrosion-damaged and mechanical-damaged tanks allow for minimum downtime. Cost effective solutions are individually developed for each client and tank application.

Maintenance inspections at ten yearly intervals benefit the long-term serviceability of the tank allowing programmed repairs and maintenance to be cost effectively programmed and delivered.

Tank lifting using specialist automated jacking systems allows repairs to be completed in a safe and efficient manner. Tank lifting allows foundation repair, product conversion, and floor replacement.

Utilising specialist automated equipment and facilities our team of highly skilled engineers consistently deliver quality repairs and maintenance in a safety-first working environment.

Tank capacities regularly delivered range from 1ML to 100ML for water, condensate, diesel, crude, bitumen, fuels and acid product storage.

We have over 100 years’ experience fabricating:

- Tank plates, including rolling and machining

- High volume traceable pipe spools

- Tank roof structures

- Tank stair towers

- Structural steel

- Coolers and stacks

- Conveyors

- Pressure vessels